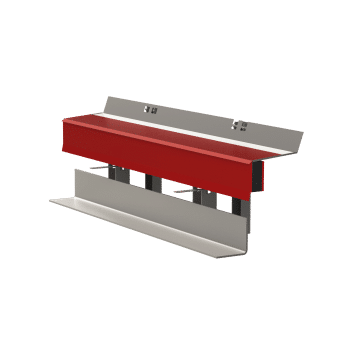

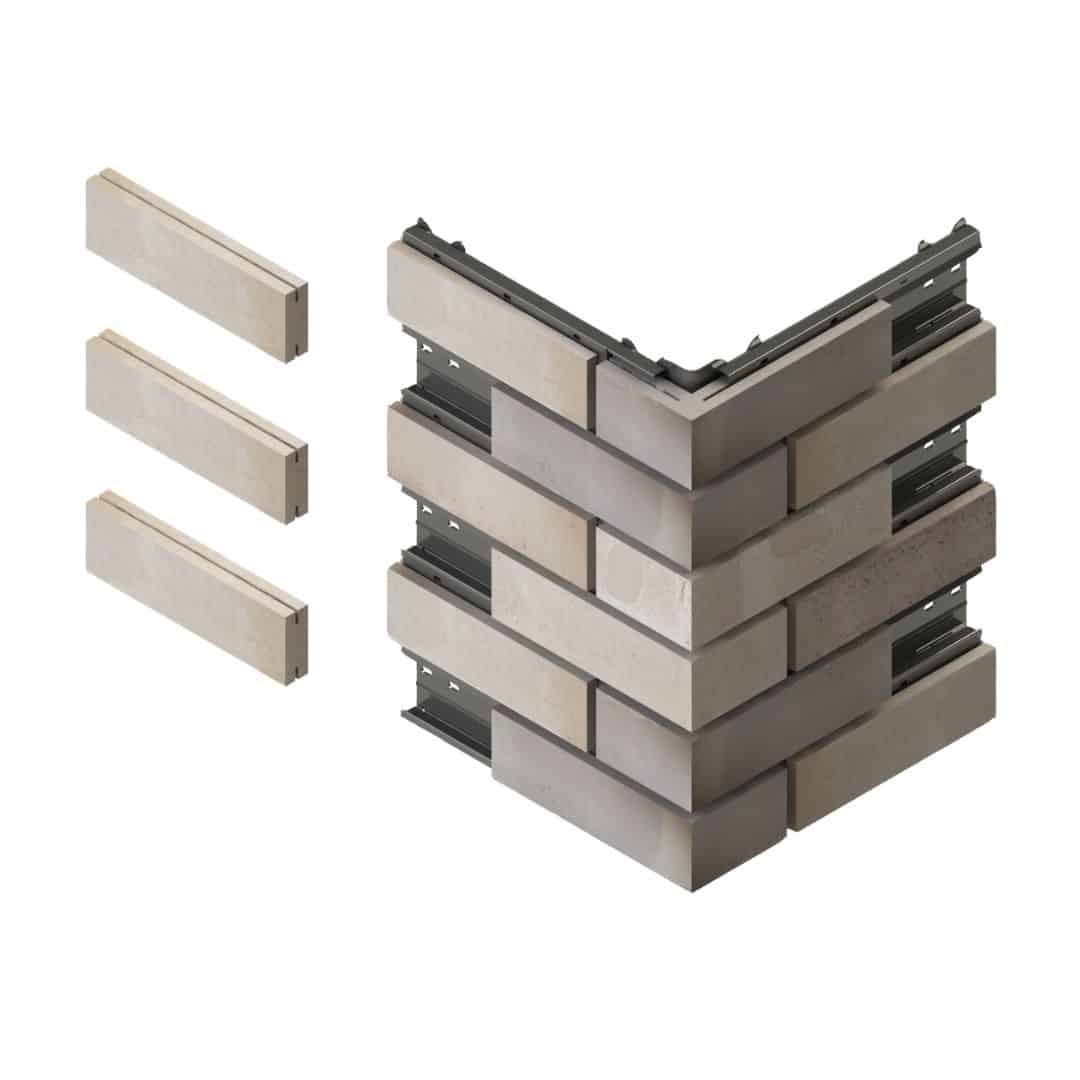

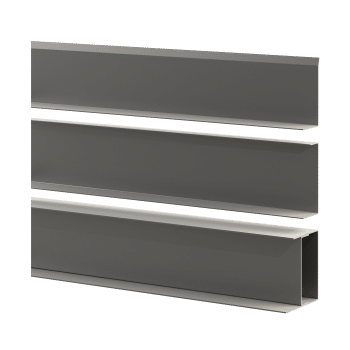

All Products

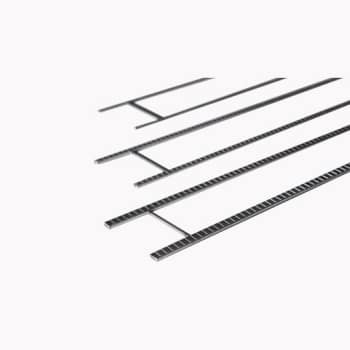

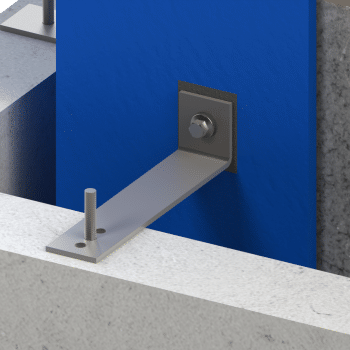

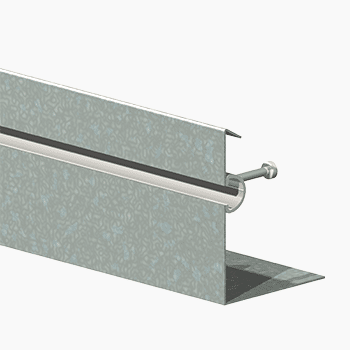

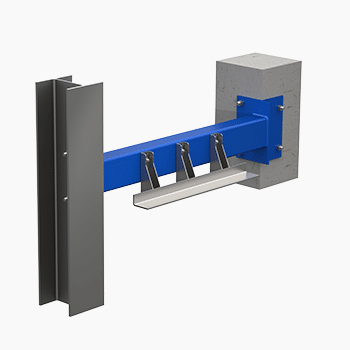

ACS design and manufacture a wide range of masonry support and structural building components. Each high-quality product is designed and manufactured to meet and often exceed construction requirements, ensuring you can specify our products with confidence, safe in the knowledge that all are compliant.