Wall Ties

Our cavity wall ties, frame cramps and channel ties set the industry standard. Made from high quality, corrosion-resistant grade 304 or grade 316 stainless steel, they’re built for longevity and reliability. Our products are trusted by some of the biggest names in construction for high rise buildings of all kinds across the UK.

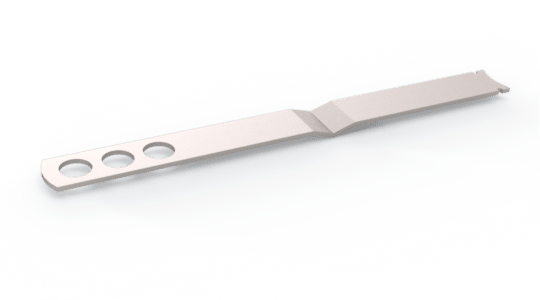

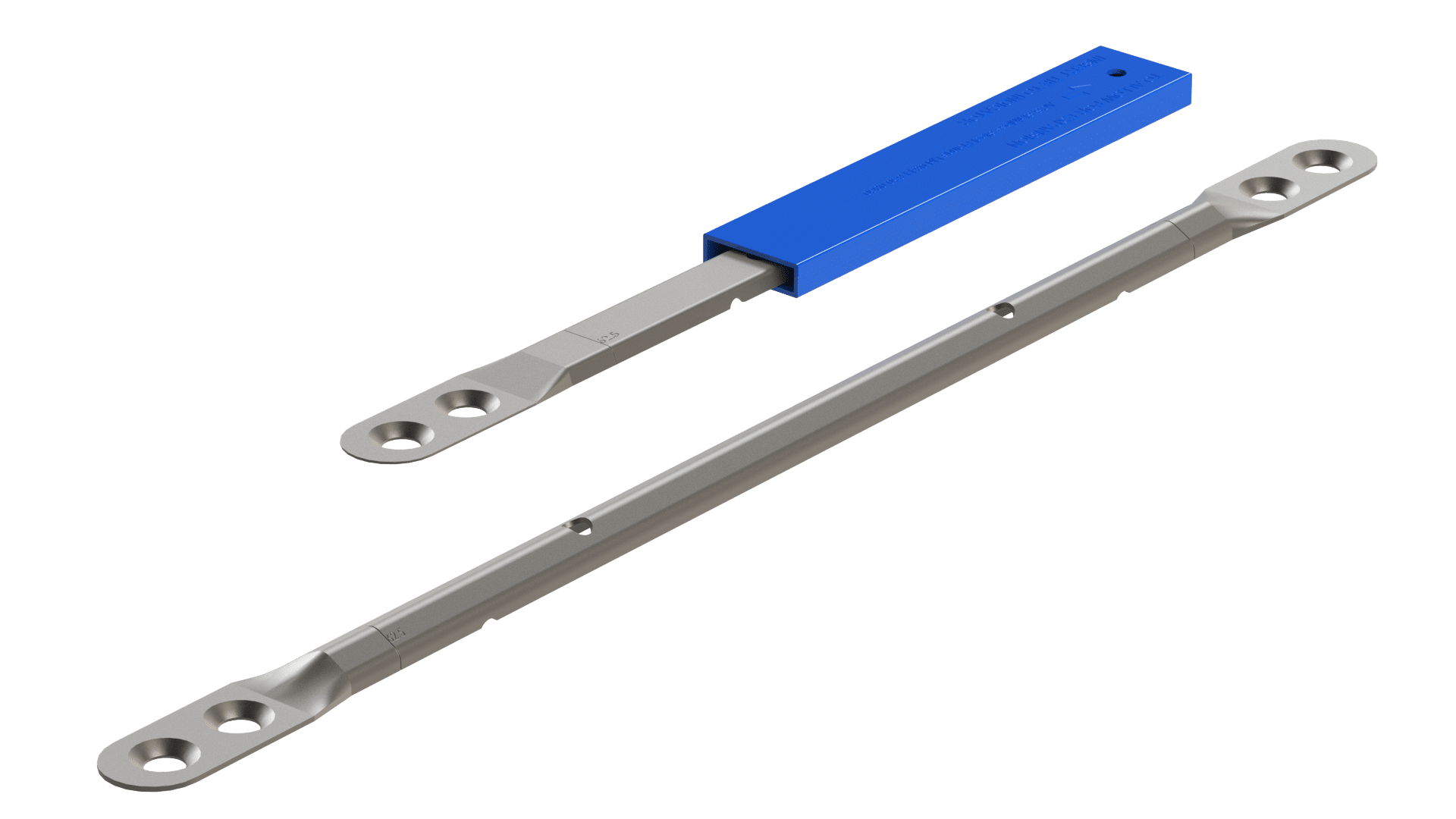

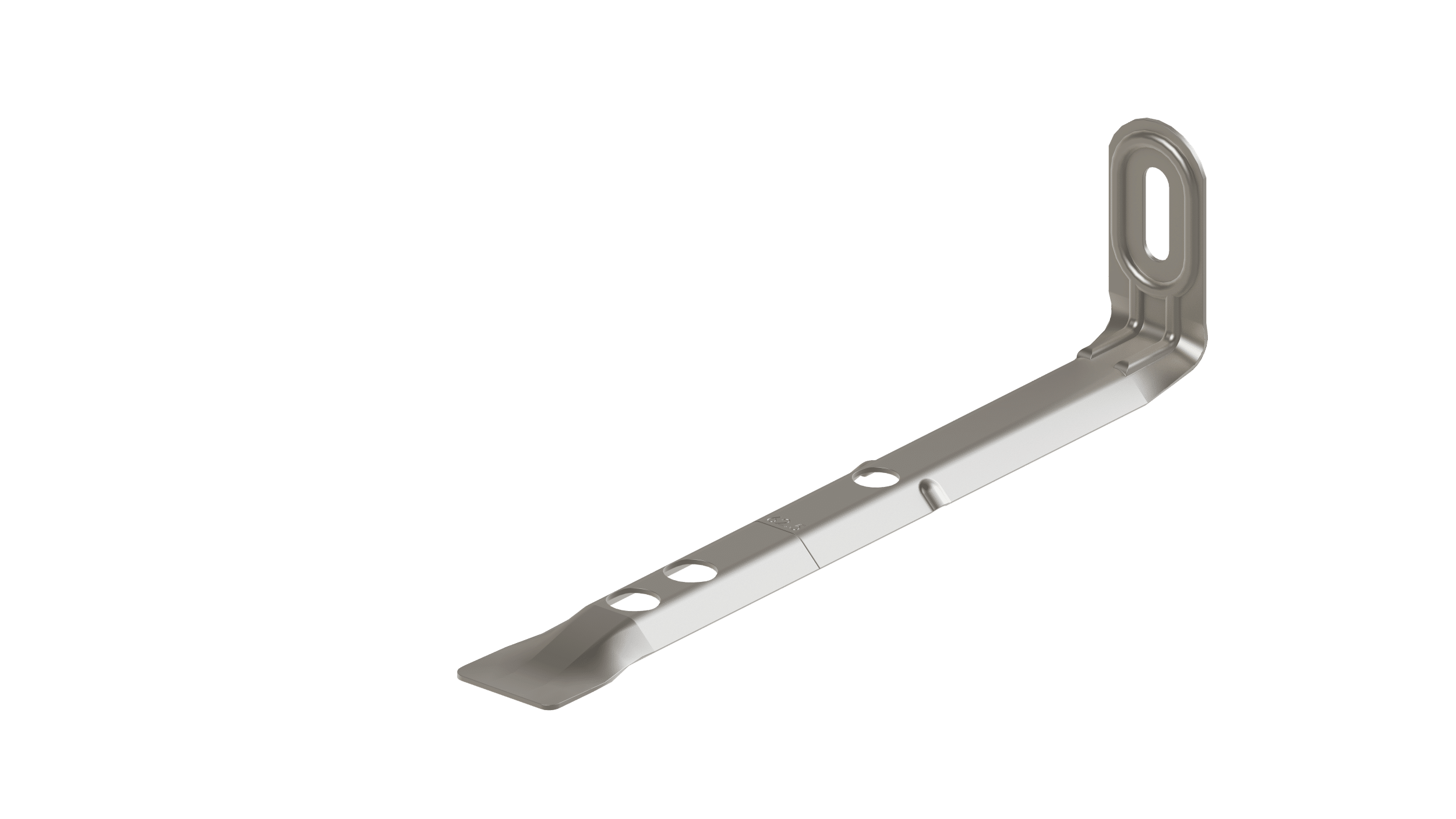

A range of stainless steel ties including ACS 2000, the UK’s first formed, fully debondable wall tie.

Superior options for tying masonry panels back to the internal leaf or primary structure.

Designed to work with channels such as our ACS 25/15 FrameFix Channel.

The ACS difference

Order from us and you get much more than exceptional products. We’re renowned for our customer service and our in-house design and product management teams help you find exactly the right products for your project, even if that means creating a bespoke product.

Availability that’s second to none

We pride ourselves on our lead times. We hold the largest stock of stainless steel cavity products in the UK, so we can often react quicker than other suppliers.