The issue of defective building materials in the construction industry has gained significant attention in recent years, particularly in the context of re-cladding projects in the UK. The presence of faulty materials, often identified years after the initial construction, poses substantial challenges for asset owners, regulators, and the construction industry as a whole. In this blog, we will explore the pitfalls associated with re-cladding UK buildings affected by defective materials and discuss potential strategies for addressing these challenges.

A blog by Jason Hedge, Strategic Design Director

Having visited many sites over the past 12 months, it still fathoms me how many issues can lurk behind the façade and in the cavity. The identification of defective materials is a complex and multifaceted process. The most common issues include the use of flammable cladding materials, inadequate insulation, and substandard or incorrectly fitted structural components such as wall ties. The Grenfell Tower tragedy in 2017 highlighted the devastating consequences of using inappropriate materials in construction, prompting a re-evaluation of building safety standards.

RE-CLADDING PROJECTS ARE OFTEN ASSOCIATED WITH SUBSTANTIAL COSTS

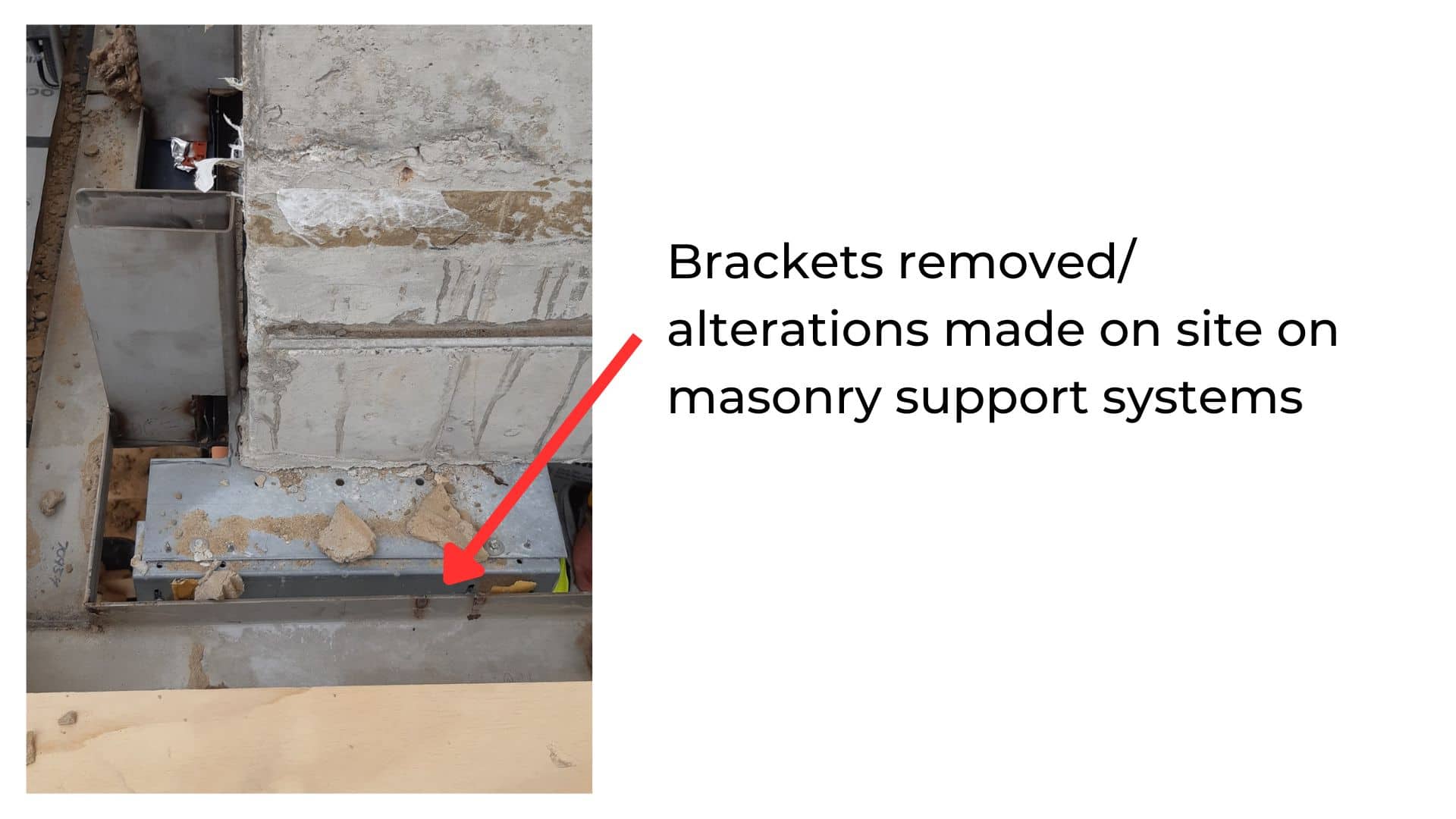

This is particularly when defective materials are involved. Asset owners may face unexpected expenses, due to the need for specialised expertise, extensive testing, and the replacement of large sections of the building envelope. Budget constraints can hinder the implementation of necessary remediation measures. Over the last few years, I’ve inspected many sites, to assess whether the masonry support and associated products are fit for purpose, and I’m always asked if they can be re-used to save on costs.

My stance on this is clear. Under no circumstances should any component be re-used. As you can imagine this doesn’t always make me popular, but it’s absolutely the right decision to ensure the safety and longevity of the building and the people who will live or work in it. It also protects the owner of the building/asset.

LET ME EXPLAIN THE REASONS WHY…

- As awareness of building safety grows, regulatory standards are evolving. Re-cladding projects must not only address existing defects but also comply with updated building codes and regulations. Navigating these changes can be challenging, requiring close collaboration between building owners, contractors, and regulatory authorities.

- As many of the buildings were constructed around 10 years ago, standards and regulations have changed significantly, therefore, what was supplied then may no longer be fit for purpose under the new requirements and will be subject to re-design to provide a warranty. A good example of this is changes to the building regulations, especially with regards to fire, as there needs to be a lot more consideration at the slab edge. Products such as masonry support, fire barriers and cavity trays must be designed together and not in isolation.

- With any building work, warranties will be required, however, should any component be re-used then any product warranty or collateral warranties that may still be effective will be treated as invalid leaving asset owners exposed to risk.

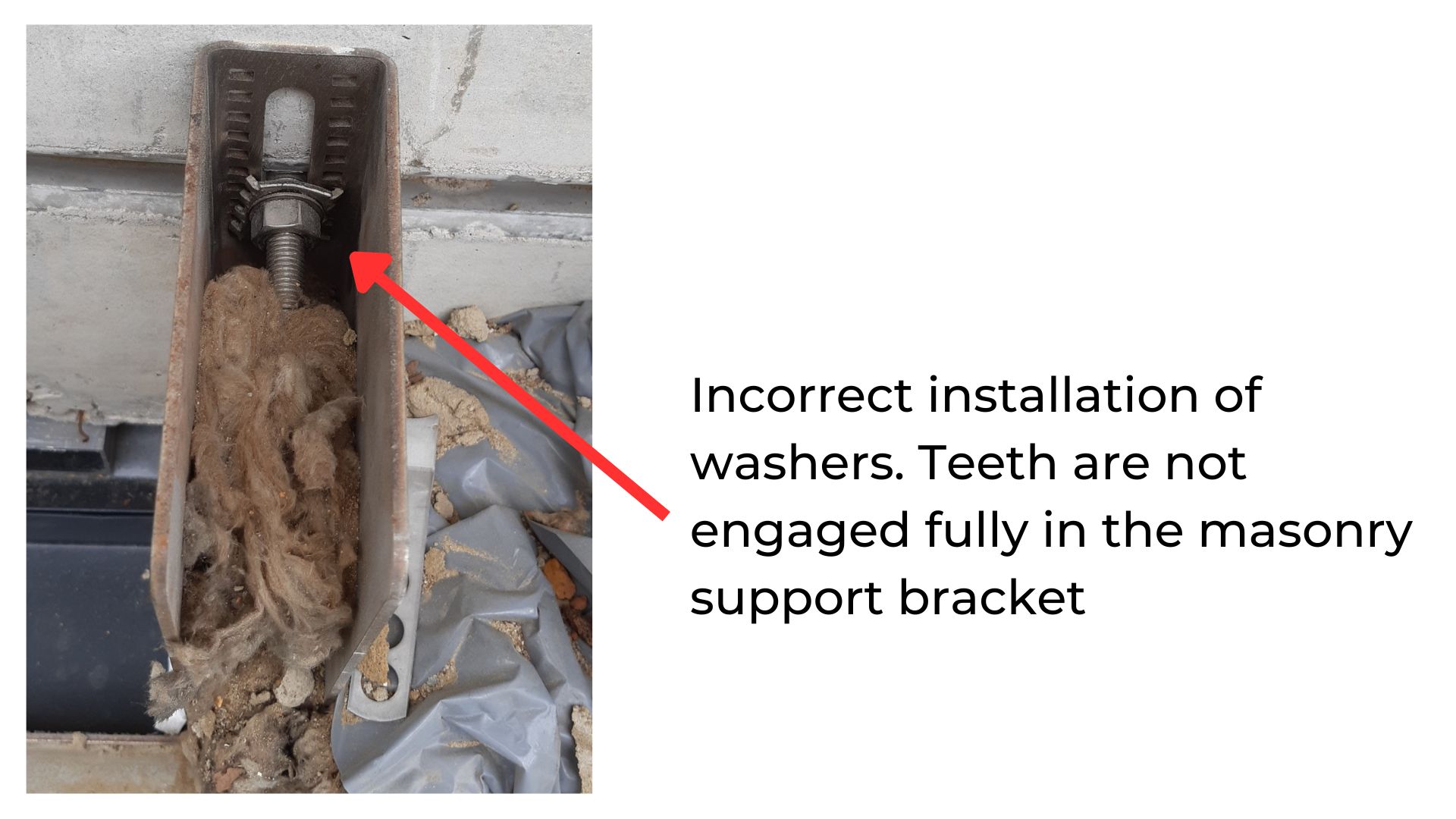

- During the demolition stage components can be subject to damage and/or over-stressing due to changing of loadings from the designed intent, which may not be visible to the naked eye, such products should, therefore, be redesigned and replaced to avoid any potential failures.

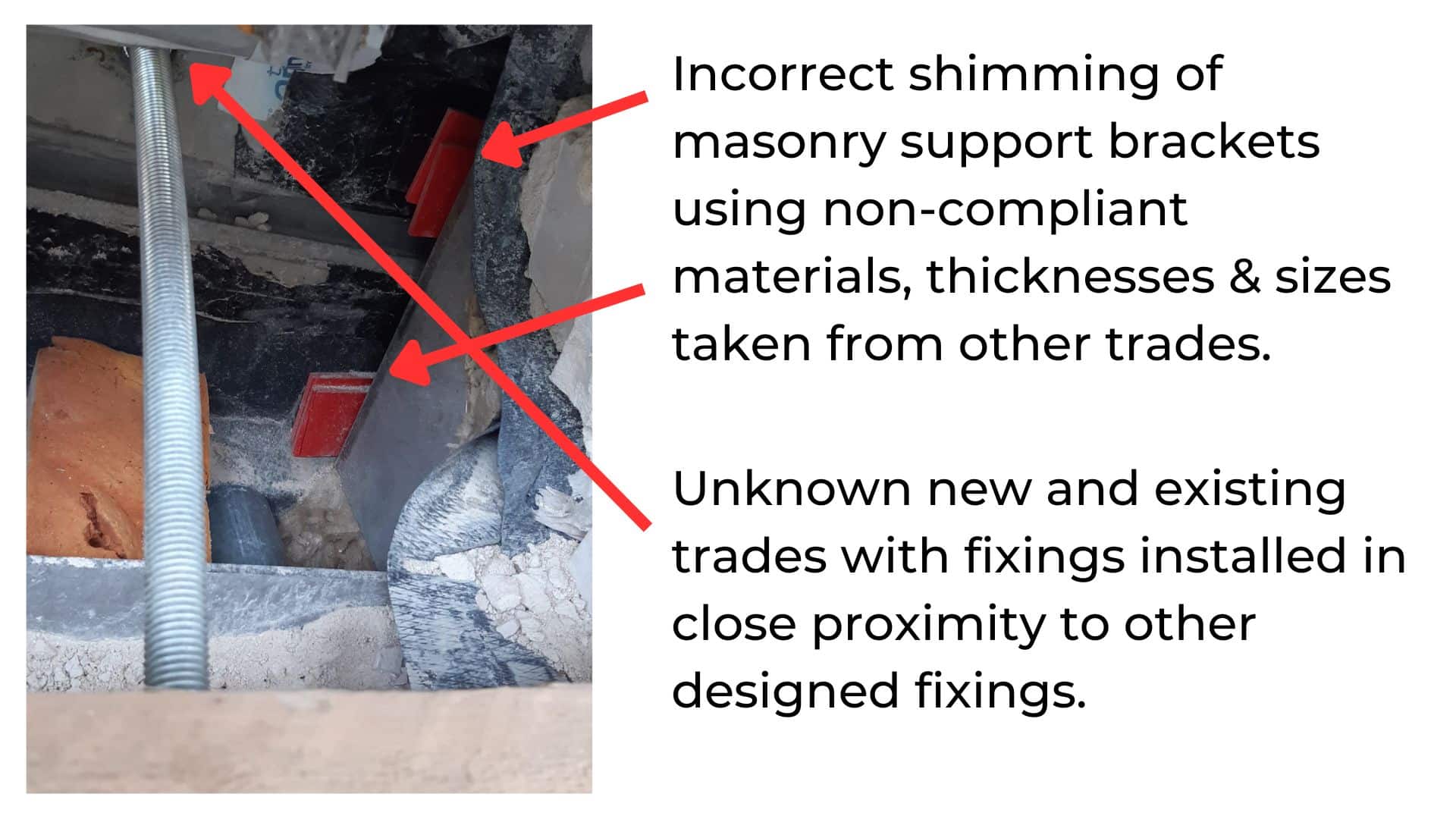

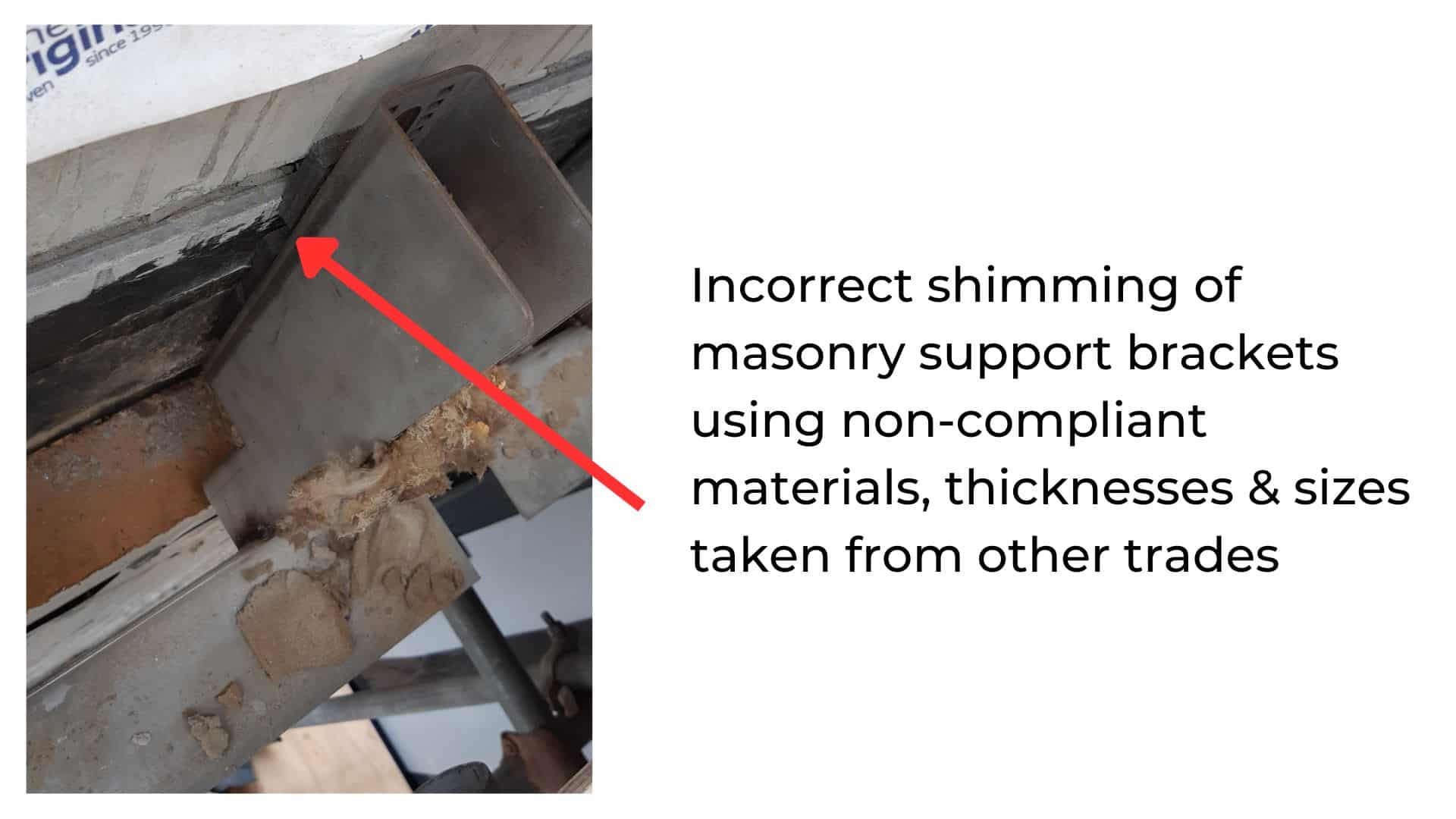

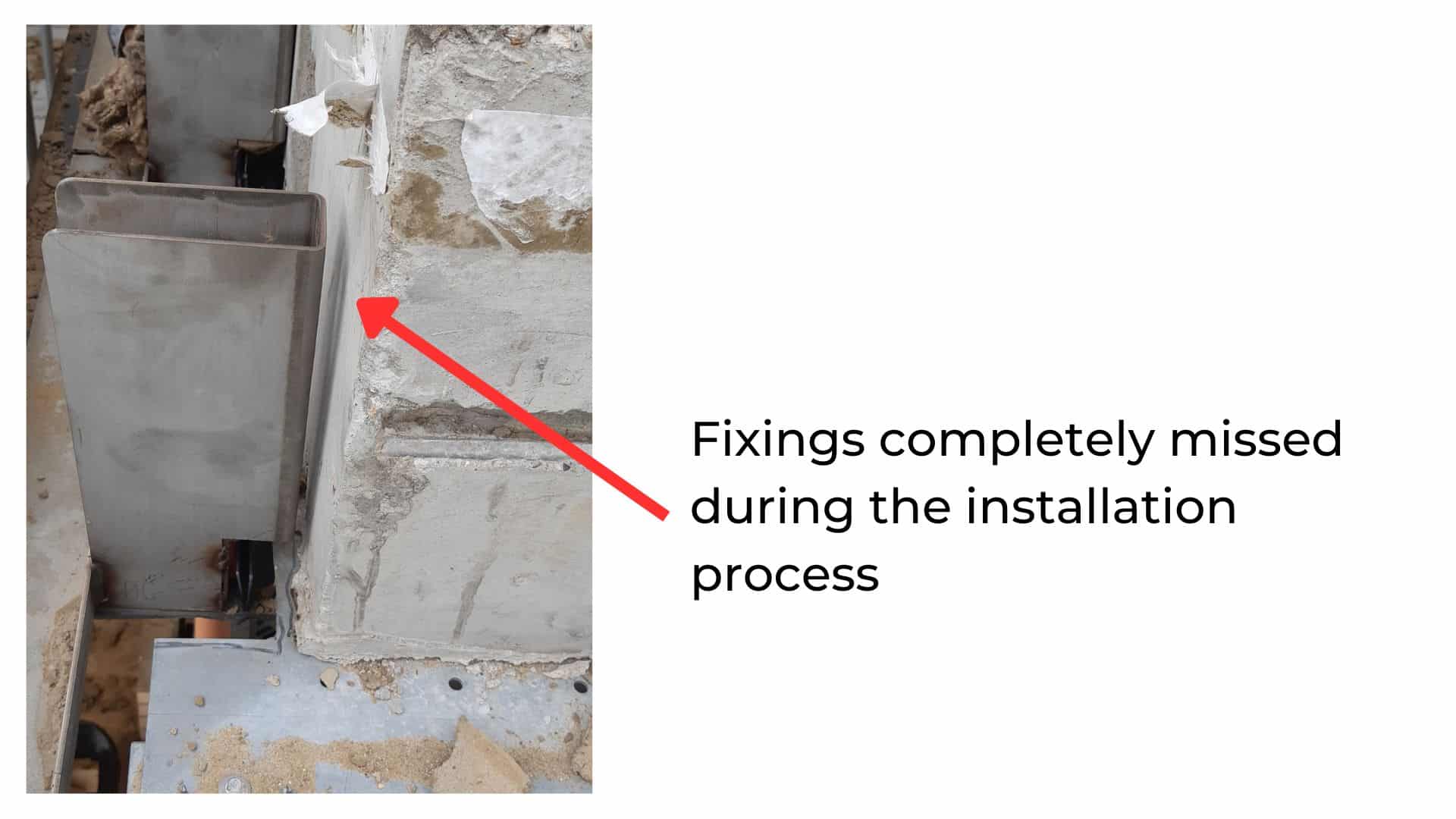

- Depending on the fixings used it may be necessary to resupply and re-fix in an alternative location due to the fact certain anchor types cannot be reused or re-torqued. This will require components to be redesigned to miss the existing holes and take into consideration other fixings from other trades used in the substrate, which would not be known until a full site survey is carried out. It is, therefore, important to follow the guidance contained within BS8539.

- The installation of existing products, such as masonry support, was based on the tolerances identified during the original build process. Obviously, any re-cladding would be subject to new tolerances (vertical, horizontal, and lateral), to which the existing products would not be installed to accommodate.

THE ULTIMATE SOLUTION

Re-cladding UK buildings marred by defective materials and compromised structural components is a multifaceted challenge. To navigate the pitfalls inherent in such projects, a comprehensive and collaborative approach is imperative. Asset owners, regulators, and the construction industry must join forces to tackle incomplete records, manage costs, and comply with the ever-evolving standards. By learning from past missteps and embracing proactive strategies, we can collectively strive towards creating safer and more resilient built environments.