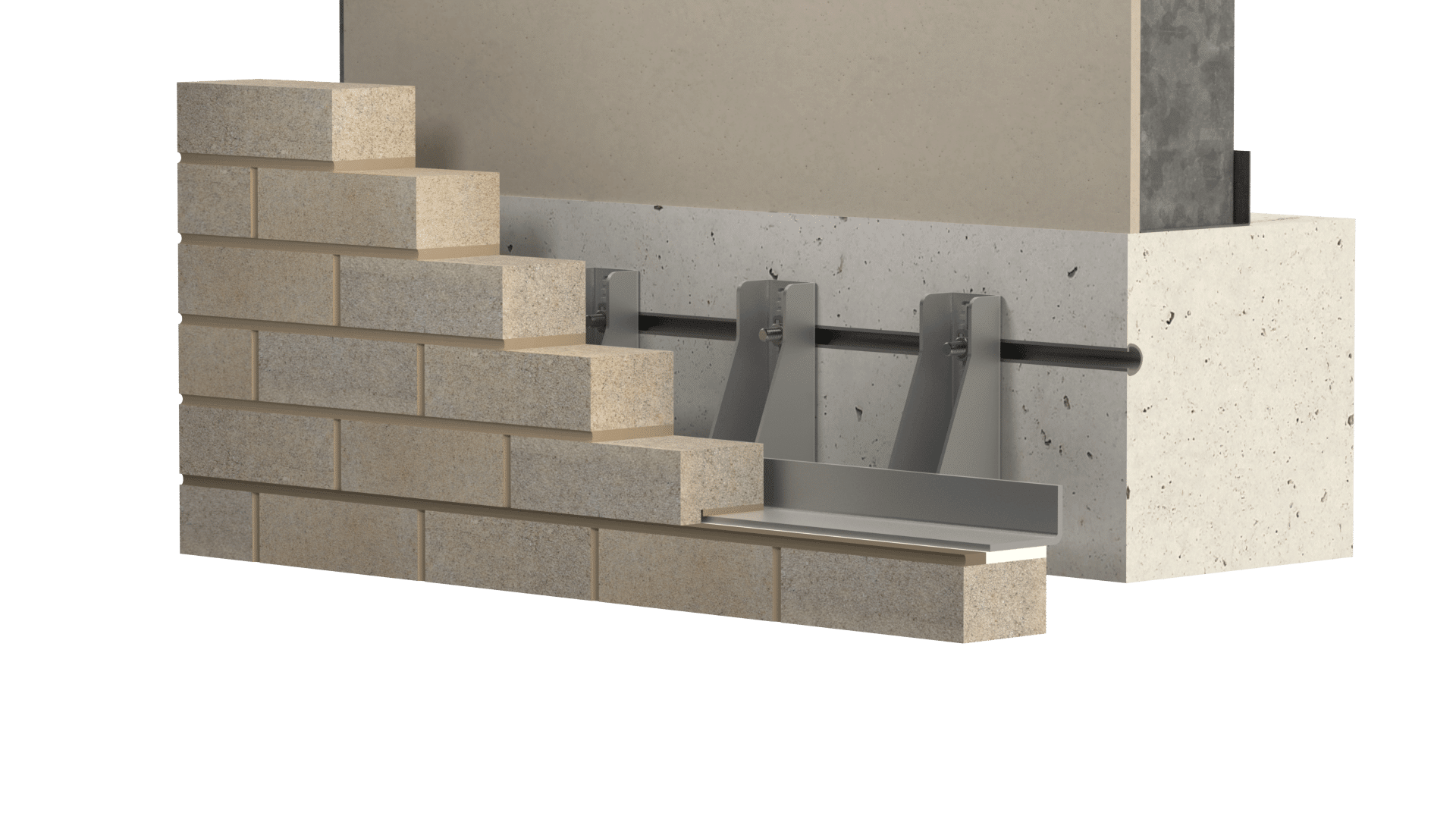

Masonry Support

Leading the way in Masonry Support.

For over 40 years we’ve been pushing what’s possible in the world of masonry support. Our products are constantly evolving, and we work with some of the biggest developers and most famous architectural practices in the country. Plus, our advanced processes help us deliver customer projects faster than other manufacturers.

Complex building? Bring it on.

Every Masonry Support product we make is built to order. Our in-house technical and structural engineers can design bespoke products that allow you to complete projects with intricate designs, large cavities and unconventional brickwork coursing.

This website includes a selection of our most popular fixing configurations. But our technical department can handle anything. So, if you have a “special” that needs input from our specialist design engineers, talk to us and we’ll be happy to meet your exact specifications.