Changes to building requirements brought on by the learnings from the Grenfell disaster has seen an increase in the use of mineral wool insulation in conjunction with brick tie and channel systems. Manufacturers such as Rockwool and Knauf have both seen demand rise for their non-combustible insulation.

The requirement for Compression Sleeves

Phenolic insulation was widely used on high rise construction projects. This rigid insulation solution provided a stable base to fix FrameFix™ channel through to the SFS. However, the increase in the specification of compressible mineral wool insulation has prompted ACS to investigate the effects of the change and what can be done to reduce any movement now present within the system. As with any change in product usage, ACS always test our products to ensure they are compliant and safe.

ACS requested independent testing based on our initial discovery to verify our results and findings. This allows ACS to give an unbiased overview of the findings and pass the knowledge onto the industry.

Testing

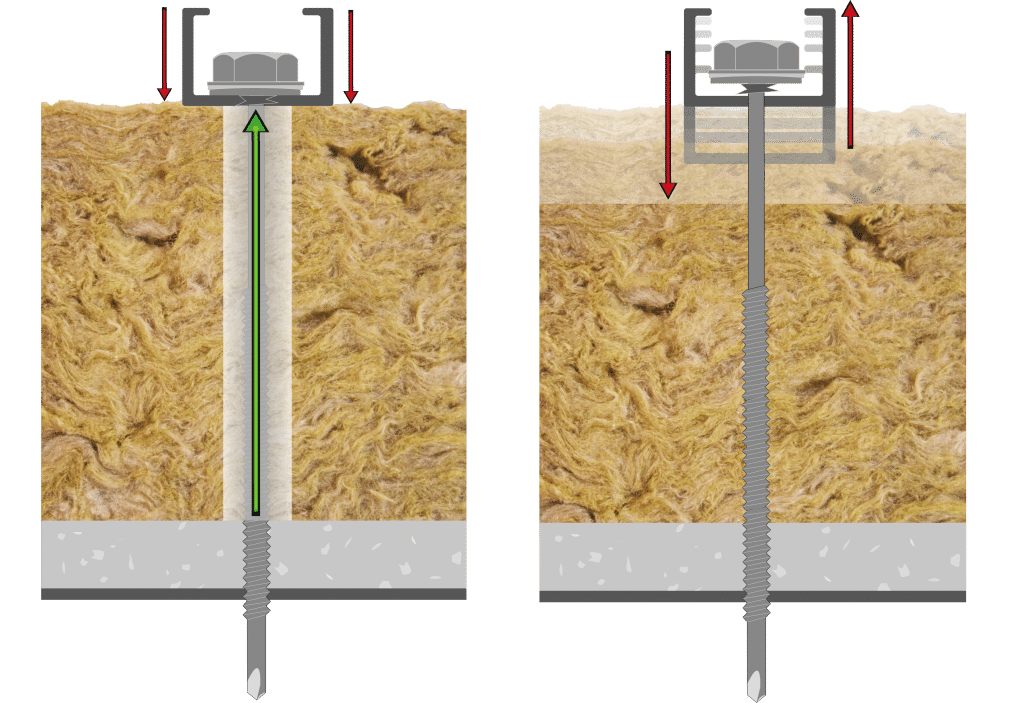

The testing of the system was performed by applying a simulated wind load onto brick tie channel, testing was performed on systems with and without compression sleeves.

The tests clearly demonstrated multiple methods of failure:

WindloadDuring testing, replicating normal wind loads it was found that the system without compression sleeves was likely to fail by shear of the ‘Hi-Thread’ of the tech screw, subsequently allowing the channel to move freely along the plain shank of the screw. |

Tie EmbedmentDuring installation, the compression sleeves ensure the channel can not be overtightened crushing the mineral wool. Inconsistent crushing of the insulation may prevent your channel ties from reaching their minimum embedment depth, therefore, failing industry requirements. |

RIgid/solid fixWithout compression sleeves, screws can be installed at an angle. Testing demonstrates that any installation of a screw with a deviation equal to or exceeding 5° caused excessive bending of the screw, allowing the deflection to take place. Compression Sleeves ensure the screw is installed level, removing any issues found with screw bending. The Compression sleeve also gives the channel something solid to be fixed to, this instantly makes the system solid and removes any movement which is present in systems that do not use compression sleeves |

A Fourth issue was identified by a representative from a respected mineral wool manufacturer who was also present during testing:

Thermal TransferWithout compression sleeves, the mineral wool is easily compressed removing the air pockets from the product which prevent thermal transfer. The crushing of the mineral wool compromises the system and reduces the ‘U value’. In essence not meeting the insulation properties required to achieve compliance. |

AestheticsBesides, the aesthetics of the installation are vastly improved. Not only does a neat installation promote best practice, but it also looks good for the client and allows for a proper inspection and consistent cavity. |

The above diagram demonstrates that with compression sleeves (left) when a load is applied to the channel the sleeve prevents deflection and ensures the pressure is not applied to the Hi Thread of the screw. Whereas the diagram without compression sleeves (Right) shows that when a load is applied to the channel, excessive pressure is applied to the Hi Thread of the fixing, potentially making the system fail by shear which would allow the channel to deflect up and down the length of the plain shank of the screw.

Overview

To summarise, the requirement for compression sleeves should not be ignored, without a compression sleeve, any brick tie system will have excessive movement during installation. As well as excessive pressure being transferred onto the ‘Hi-Thread’ of the fixing, which can cause the screw to fail by shear. Poor installation of the fixings can allow bending of the screw can occur, which, in turn, could promote bending of the screw during windload.

Also, inconsistent embedment of wall ties caused by crushed mineral wool may cause cracking within the facade, the crushing also reduces the ‘U value’ of the insulation; therefore not being as insulative as the manufacturer states and ultimately not meeting the required standard specified.

All of these issues as a group and individual issues on their own clearly demonstrate the requirement for compression sleeves.

Compression Sleeve Material

ACS compression sleeves have extremely high compressive strength and almost negligible thermal transfer rate. All sleeves are made of fire-resistant material, However, as OEM component/thermal break, they do fall outside this classification as outlined in the requirement; exclusions from classification requirement.

ACS believes it is important to ensure our products are safe and compliant, that’s why we have insisted on using a unique composite material that prevents thermal transfer whilst still providing high compressive strength and fire resistance.

Other manufacturers have released fireproof sleeves however these are generally made of stainless steel which acts as a thermal bridge, causing cold spots and promoting condensation within the sleeve itself. Insulation manufacturers advise against the use of thermally conductive sleeves as this can have a detrimental effect on the stated U-value of the product. Condensation within the sleeve can be a major issue when coupled with zinc tech screws which, over time will begin to corrode – ACS only supplies stainless steel screws with compression sleeves to alleviate this issue.

Avoid costly remedial work

If a brick facade begins to crack, the costs incurred in the repair and possible reinstallation of the facade will be time-consuming and costly. Not only is a cracked brick facade expensive to repair, but it is also highly dangerous to the public living and working within the vicinity.

ACS was the first manufacturer to design and develop compression sleeves after being approached by two leading insulation manufacturers; concerned that their product’s performance would be affected if compressed by channel. ACS is the only manufacturer to insist on the use of compression sleeves within the FrameFix™ solution since the learnings of the Grenfell disaster were publicised. Our FrameFix™ system is CE rated, warrantied and indemnified giving you total peace of mind when specifying our products.

Working With Manufacturers and Installers

ACS was approached by both Rockwool and Knauf to provide a suitable solution to prevent the crushing of compressible insulation as they believe it adversely affects the U-value of their product. We have collaborated with manufacturers and installers to provide a fully tested solution suitable for the UK market.

For more information about our compression sleeves or FrameFix™, please feel free to contact our technical department technical@acsstainless.co.uk or call 0844 850 0860

Related Articles

16th October 2018

CE Marking and the (CRP) Law

From 1st of July 2014, the CE Marking of welded and fabricated structural steel products becomes man...

read more

23rd October 2018

Fire Detailing: Stainless Steel Structural Building Components

Historically, masonry walls have demonstrated excellent fire resistance, provided that the foundatio...

read more

Article originally published on 20th November 2018