When designing anchors for use in a concrete substrate, it is important to understand the impact of ‘cracked concrete’ and its effect on the specification of an anchor.

Why does concrete crack?

Concrete as a material is inherently strong in compression, but weak in tension in comparison. For this reason, steel reinforcement is positioned within the concrete member where the tension zones occur. In these tension zones, small cracks naturally occur as the concrete deflects under the design load. It is these so-called ‘micro-cracks’ that must be considered within the design and correct specification of the concrete anchor.

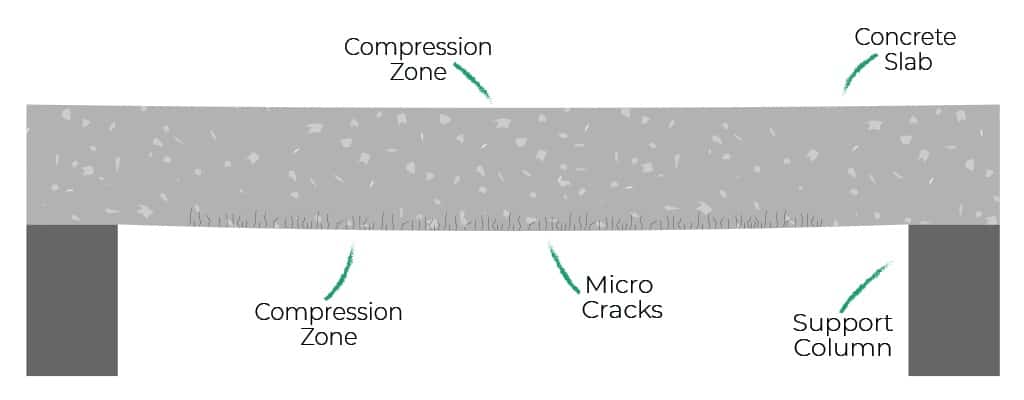

On a standard slab over two supports, the compression zone will be found in the top of the slab, and the tension zone found in the base of the slab (as seen below).

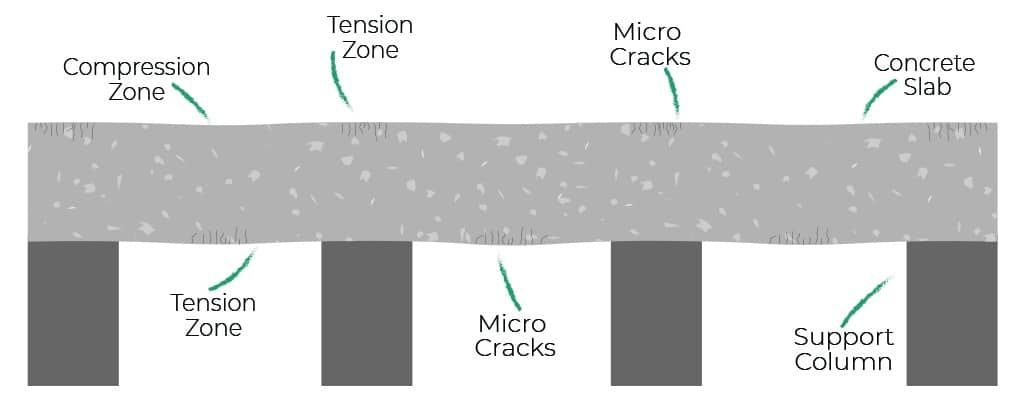

However, in practice, a slab is continuous over multiple supports. Over these supports, the tension zone is located at the top of the slab and in the compression zone at the base meaning the cracked condition will vary throughout a slab depending on the location of supports.

Concrete is likely to be cracked from a variety of causes including stress conditions inherent in the structure, those induced by characteristic permanent actions and characteristic variable actions, thermal movements, shrinkage and the restraint of deformation.

All of these factors make correct anchor specification a challenging process to ensure the anchor is designed for the conditions in which it will be used. It is therefore important to consult the relevant standards.

BS EN 1992-4:2018, the new Eurocode sub-standard for concrete anchors, states that uncracked concrete can only be assumed if it is proven that under the characteristic combination of loading at serviceability limit state, the fastener with its entire embedment depth is located in uncracked concrete.

Essentially, it cannot be assumed that concrete is uncracked in all cases. An assessment must be made of whether the concrete is cracked or uncracked for each anchor location. With masonry support, anchors are generally installed at the same level horizontally along the slab edge. Based on the theory above the opportunity arises for some of the anchors to be installed into cracked concrete, and some to be installed in uncracked concrete. Therefore, to avoid confusion and the potential for the incorrect anchor specification, a safe approach would be to assume that the concrete is cracked in all conditions over its service life.

Another relevant standard to the selection of anchors and cracked concrete is BS8539:2012, The Code of Practice for the selection and installation of post-installed anchors in concrete and masonry. This standard provides recommendations for the safe selection and installation of anchors for use in concrete and masonry. This again states that concrete should be assumed as cracked unless an exercise has been carried out to determine whether it is cracked or non-cracked.

Following the guidance from the standards that cracked concrete should generally be assumed where no slab assessment has been carried out, an anchor should be selected which has an Option 1 ETA. Option 1 anchors have been tested in both cracked and uncracked concrete and are specifically designed to be fit for purpose with concrete in the cracked condition. Anchors designed and tested in uncracked concrete only will have an Option 7 ETA and are not suitable for use in cracked conditions.

Uncracked concrete, an assumption too far?

Following the update to BS EN 1992:4:2018, ACS has changed the way we specify what type of anchor to be used with our products. Currently, its standard practice to allow the engineer or contractor to decide on the type of fixings used, however, ACS will now specify cracked concrete fixings on all new projects from the 3rd of October 2019. The switch to the superior fixing method removes any guesswork or assumptions from the process. To find out more about this change, click here

Related Articles

30th October 2018

Why Choose ACS Masonry support

At ACS we manufacture our masonry support system to the highest standards. Our manufacturing process...

read more

30th October 2018

Types of Channel

What types of channel are there? Cast in Channel Cast in channels is split into 2 groups, self-ancho...

read more

Article originally published on 30th September 2019