Our journey so far

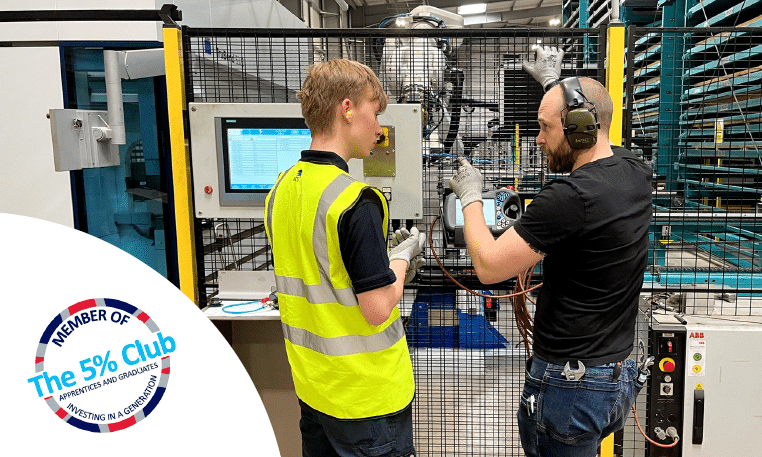

We are members of the 5% club, a commitment to furthering the number, quality and range of earn and learn opportunities across the UK.

The ACS apprenticeship programme partners with top educational institutions like Leeds College of Building, Leeds City College and TTE Training to provide hands-on experience and expert mentorship. Our apprentices gain practical skills and industry knowledge, preparing them for successful careers in construction and manufacturing.

Whilst we are still early in our journey, we are delighted to have been recognised with the ‘Manufacturing Future Talent Award’ at the 2024 Made in Yorkshire Awards, with judges noting that our “ongoing commitment to employee training and performance” stood out in the judging process!

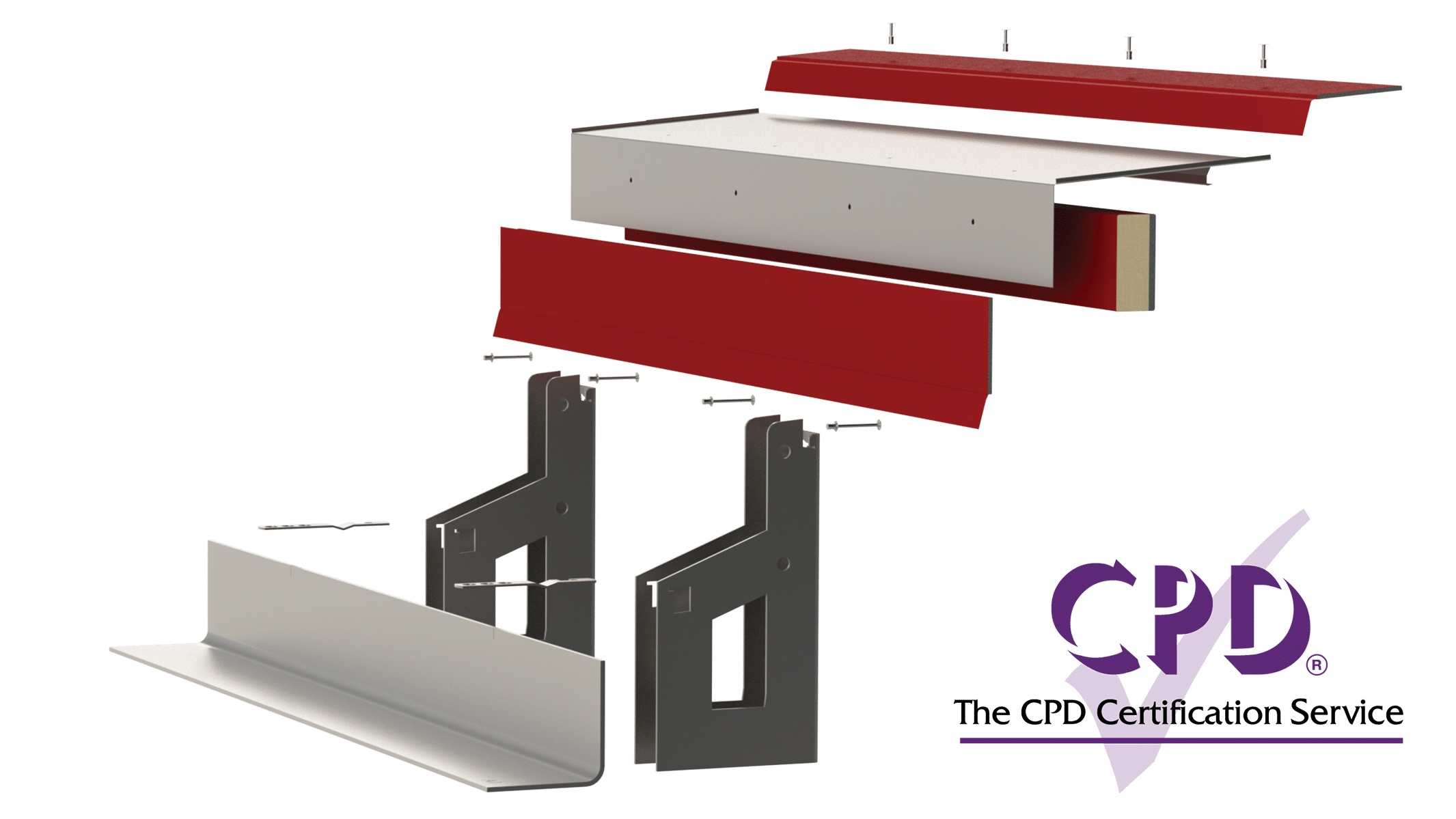

In 2024 we opened the ACS Academy, a dedicated training facility for staff and customers, featuring bespoke training rigs to provide hands on experience with our products. Through the ACS Academy, we provide factory tours, hands-on training, toolbox talks and detailed instruction on installing our key products, including Masonry Support, Cavity Trays, Intex™ 4-in-1 Masonry Support, and Certus™ and Azure II™ brick-slip systems.

We’re incredibly proud to announce that ACS has become the first in our sector to achieve Planet Mark business certification. This milestone reflects our unwavering commitment to sustainability and our dedication to making a real, measurable impact.

Planet Mark is an internationally recognised leader in net zero certification, with over 12 years of experience in helping 800+ Member organisations reduce carbon emissions, achieve net zero targets and generate long-term business value.

Our Commitment to Real Sustainability

After an intensive four-month process of data collection and analysis, Planet Mark has recognised our robust efforts in energy efficiency and social value. We’ve invested significantly in our people, generating £123,281 in social value through apprenticeships, T-Levels, and our in-house ACS Academy training programs.

This achievement marks a significant shift in our sustainability strategy. We’ve moved from carbon neutrality, which relied on offsetting, to Planet Mark certification, which focuses on tangible carbon emission reductions. As our Director of Design and Innovation, Dean Keeble, explains, “To achieve Net Zero, we must prioritise 90% decarbonisation, with only the remaining emissions offset. Planet Mark enables us to take real, tangible steps towards achieving our goals.”

First in our sector to achieve Planet Mark Certification

1.1% and 0.2% Scope 1 and Scope 2 Carbon Emissions

98.7%: Carbon Footprint Reduction Focus on Scope 3 Emissions.

£123,281: Social Value Generated Through People Investment.

Looking to the future

A key finding of the assessment was that 98.8% of our carbon footprint comes from Scope 3 emissions, primarily within our supply chain. To address this, we’re conducting a comprehensive supply chain survey and actively engaging with our steel suppliers. We’re excited about the industry’s transition to innovations like electric arc furnaces and low-carbon “Circle Green” steel, which will significantly reduce our footprint.

Our Managing Director, David Flannery, emphasizes, “We are taking decisive action to reduce our impact, but we also recognize that sustainability is a collective effort. By working closely with our supply chain, embracing innovation in steel manufacturing, and continuously investing in our people, we are ensuring ACS remains a leader in sustainable manufacturing.”

At ACS, we believe that sustainability is about more than just reducing our carbon footprint. It’s about investing in our people and our community. By balancing environmental targets with meaningful social impact, we’re building a sustainable future for everyone. We are proud to be leading the way in our sector, and we will continue to push the boundaries of sustainable manufacturing.

Investing in Sustainability: Our state-of-the-art, facilities

It’s not just our people that we are investing in, our facilities are top notch too.

In 2019 we moved into our purpose-built manufacturing facility in Leeds, home to over 1,000 photovoltaic solar panels that ensure a third of the energy we consume is generated on site through renewable sources.

Auto-dimming LED lighting and maximum levels of insulation have ensured that our factory achieves an EPC rating of A, helping to reduce our energy demand all year round.

Additionally, we are making significant strides in transitioning our company vehicle fleet, with 12 EV charging points and a fully electric mechanical handling fleet already in place.

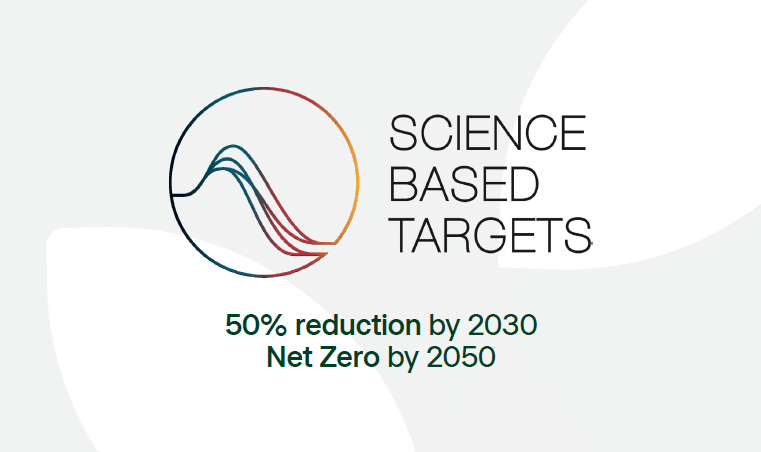

Our Net Zero target

In 2022 we measured our baseline operational carbon footprint, and we are working tirelessly to achieve a 50% reduction by 2030 and Net Zero by 2050, with our targets validated by the Science Based Targets initiative (SBTi).

The Science Based Targets initiative (SBTi) is a corporate climate action organization that develops standards, tools and guidance to allow companies to set greenhouse gas (GHG) emissions reductions targets in line with what is needed to keep global heating below catastrophic levels.

By aligning our operational carbon reduction targets with the SBTi, we are following the latest climate science to reduce our carbon footprint at the rate our planet demands.

Gold Status

We’re proud members of the Supply Chain Sustainability School, a collaborative industry initiative dedicated to building a sustainable environment. Our commitment to continuous improvement has been recognised with Gold status, demonstrating our dedication to embedding sustainable practices throughout our operations and supply chain. This achievement reflects our proactive approach to learning, sharing best practices, and driving positive change within the construction sector.

Supporting Communities: Our partnerships for Armed Forces and MND Awareness

Since 2022, we have partnered with DX Group, and the Army Benevolent Fund to raise awareness and funds for the Armed Forces. As part of this initiative, we have produced free steel Tommy soldiers for communities across the country, to be displayed during Remembrance Sunday services and events. Our efforts have grown significantly each year, with over 630 soldiers created at date, contributing to a total of £6,700 raised for charity.

We are proud sponsors of the ‘Extra Mile Challenge,’ backing rugby league legends Kevin Sinfield OBE and the late Rob Burrow CBE in their mission to raise much-needed funds and awareness for Motor Neurone Disease (MND) research. Since 2021, our contributions have exceeded £50,000, demonstrating our commitment to this vital cause.

CPD Series

CPD Certified: Non-Combustible Cavity Tray Systems

Live

60mins

Live

60mins

Why take the risk? Register for this CPD Certified webinar on non-combustible cavity trays, featuring G-Tray™ and learn from the manufacturer that developed, launched and installed the first A1 rated cavity tray in the UK.

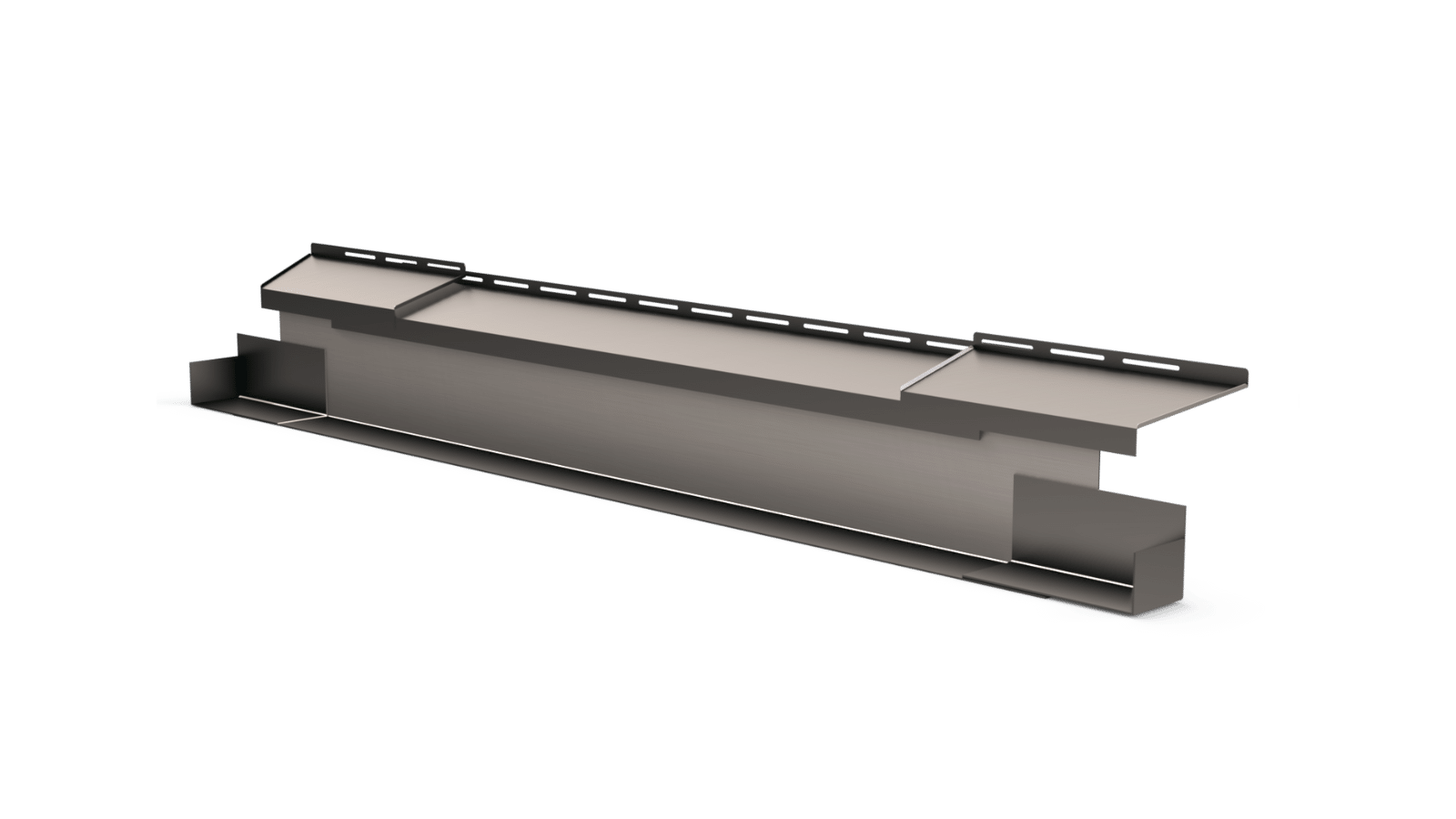

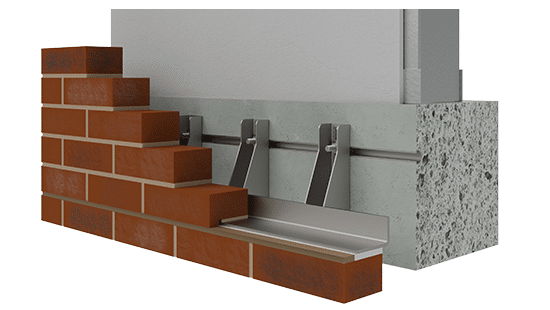

CPD Certified: Masonry Support Systems

Live

60mins

Live

60mins

Learn directly from our expert engineers about the importance of Masonry Support, and why specifying high quality masonry support early in a project is as important as laying solid foundations, to ensure buildings meet safety regulations and last the test of time.

CPD Certified: Cavity Congestion in a Masonry Façade

Live

60 minutes

Live

60 minutes

Join this CPD outlining the issues around cavity congestion in a masonry façade. This CPD focuses on addressing the ever-growing challenges and introduces innovative new strategies for solving cavity congestion in building design and construction.

This CPD features Chris Thompson, Global Product Manager from Tenmat, who explores the latest advancements in fire protection, including the benefits of Tenmat intumescent materials, and their crucial role in stopping the spread of fire and smoke.

TALK TO US ABOUT HOW WE CAN HELP