Conventional Masonry Support

ACS conventional masonry support is manufactured to meet your exact masonry support needs including intricate designs, large cavities and unconventional brickwork coursing.

Below is a selection of popular fixing configurations, however, our technical department will be able to discuss your requirements and provide solutions which meet your exact specification.

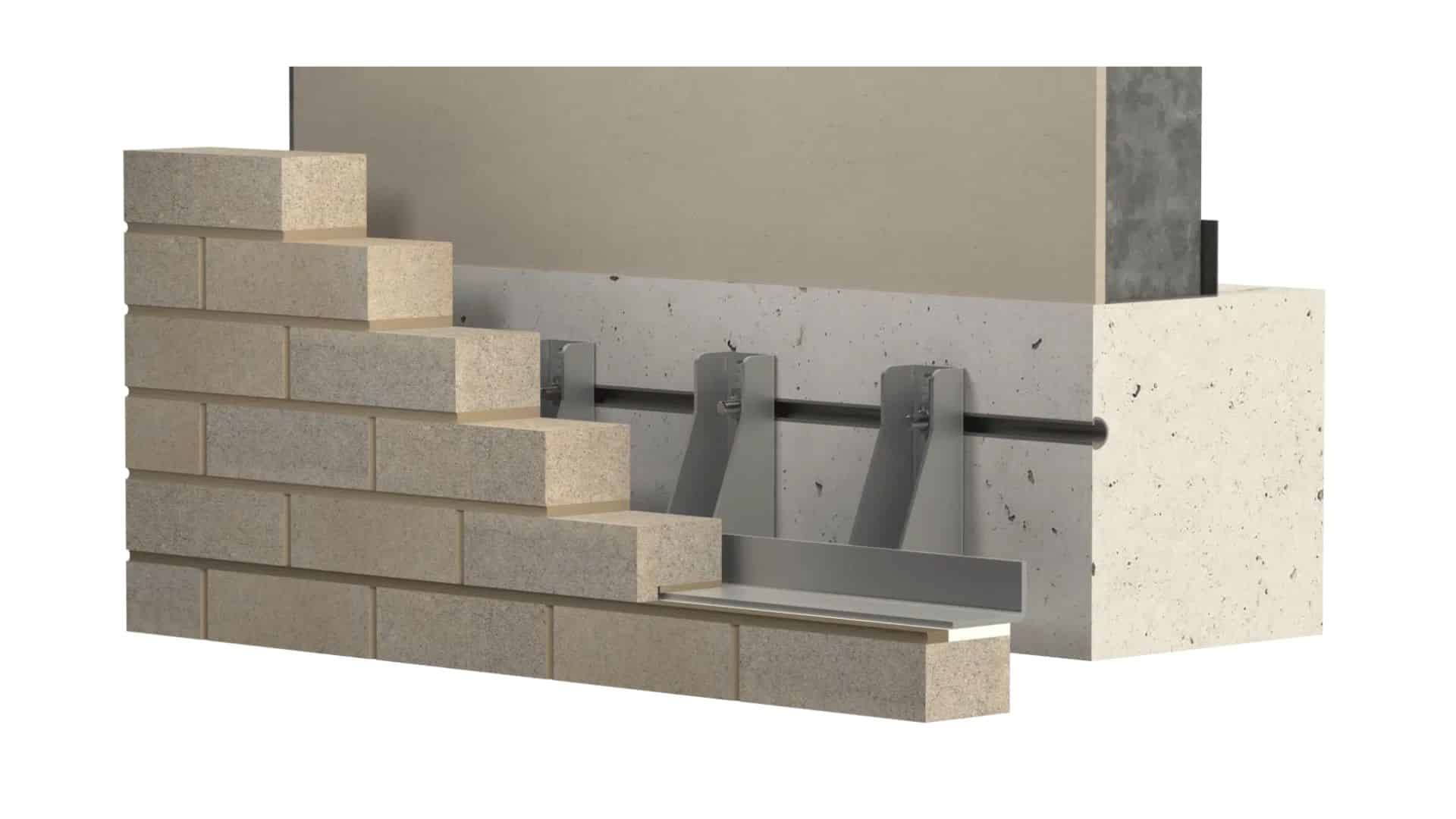

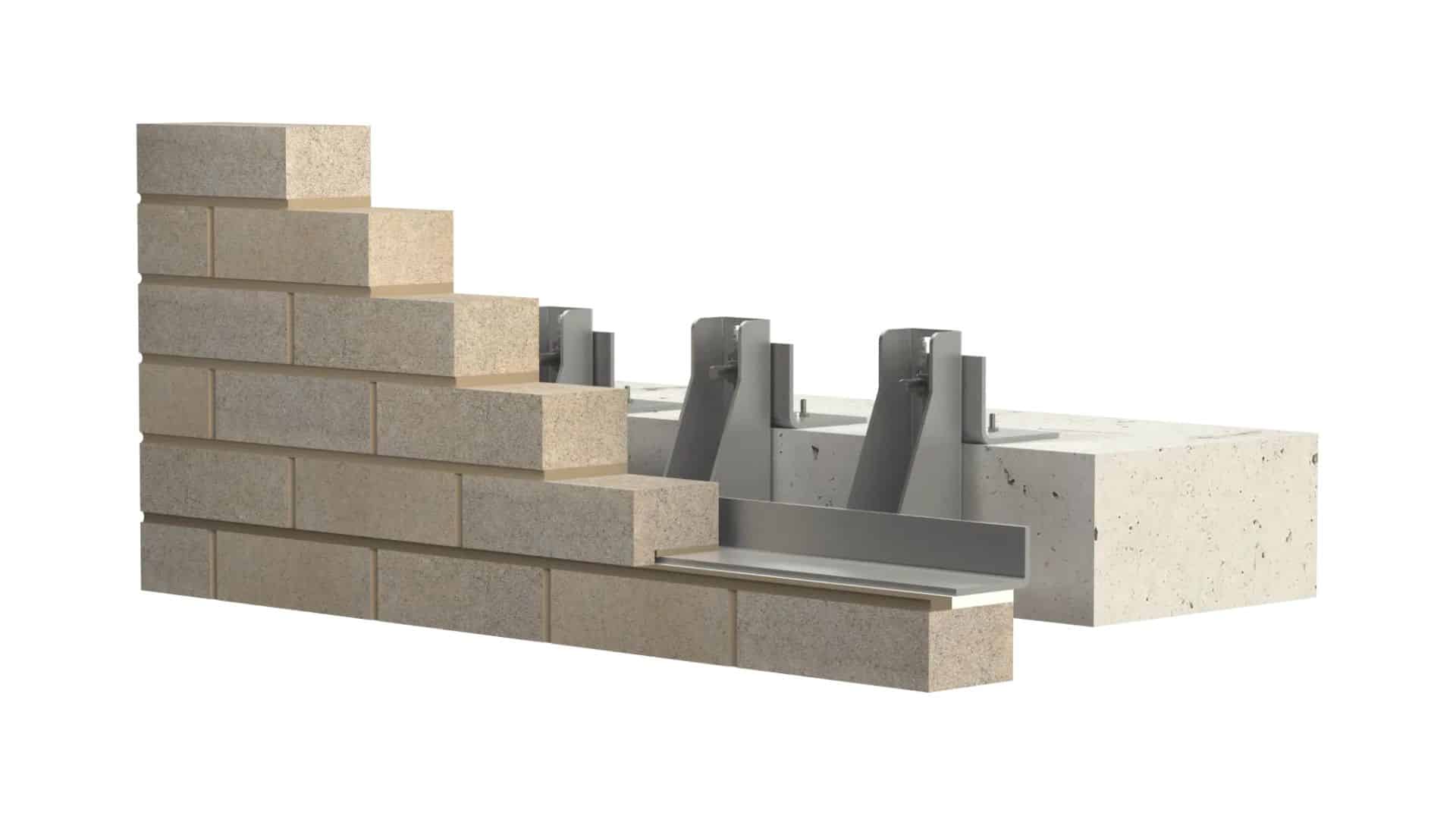

Conventional Masonry Support – Type 1

Using a continuous angle with brackets welded to the vertical leg of the angle. The brackets are then fixed to the structural frame. The most economical system for wider cavities, as the angle is kept to a minimum depth.

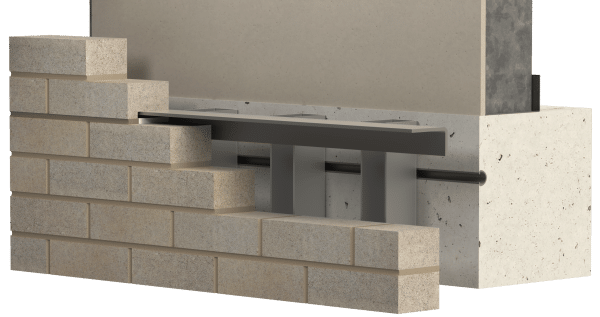

Conventional Masonry Support – Type 2

A continuous angle fixed directly to the structural frame. The efficiency of this system decreases with wider cavities.

We take clear product information seriously

That’s why all our Masonry Support products carry the Code for Construction Product Information (CCPI) mark.